01

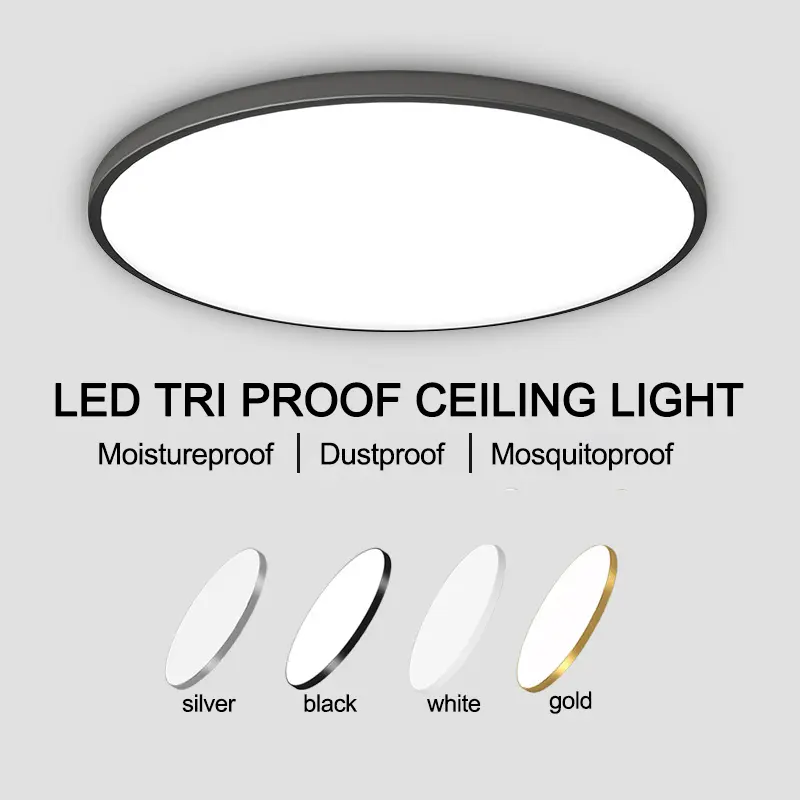

IP54 Moisture-proof Outdoor Led Tri Proof Ceiling Light YW-TLSF

Design Aesthetics

Engineered for Extreme Environmental Resilience

This professional-grade luminaire is built to thrive where standard lights fail. Its enhanced IP54 rating provides a higher degree of protection against ingress of dust and water jets from any direction, making it vastly superior for grimy, humid, or high-particulate environments. The sealed design not only prevents internal damage but also actively resists dust accumulation on LEDs and the diffuser, maintaining over 95% of initial lumen output over time and eliminating the dimming effect caused by dirt. This ensures long-term light stability, reduced maintenance cycles, and lower lifetime costs, a critical factor for facility managers.

Border Color Options

Available in black, white, gold, and silver border colors. Wholesalers can cater to different project aesthetics-the classic black and white suit minimalist interiors, while gold and silver add a touch of elegance to high-end commercial spaces like luxury hotel bathrooms or upscale mall restrooms. Engineering contractors can easily match the light to various design schemes, enhancing the overall visual appeal of projects.

Unmatched Application Versatility

This single lighting solution is engineered to meet the demands of a vast spectrum of commercial and residential applications, simplifying inventory and procurement for wholesalers. Its resilience makes it the perfect choice for:

High-Humidity Zones: Food processing areas, commercial kitchens, indoor pools, bathrooms, and underground facilities.

High-Particulate Environments: Warehouses, underground parking garages, industrial workshops, and manufacturing plants.

Public & Commercial Spaces: Subway stations, school corridors, hospital storage rooms, and retail store backrooms.

General Use: Corridors, bedrooms, and stairwells where long-life, low-maintenance lighting is desired.

High-Humidity Zones: Food processing areas, commercial kitchens, indoor pools, bathrooms, and underground facilities.

High-Particulate Environments: Warehouses, underground parking garages, industrial workshops, and manufacturing plants.

Public & Commercial Spaces: Subway stations, school corridors, hospital storage rooms, and retail store backrooms.

General Use: Corridors, bedrooms, and stairwells where long-life, low-maintenance lighting is desired.

Comprehensive Specification Range for Precise Project Matching

To provide exact solutions for any space, the product is available in a comprehensive matrix of sizes and outputs:

Sizes & Wattage: Ø230mm (18W), Ø270mm (24W), Ø370mm (36W), Ø470mm (42W). This range ensures the right amount of light for everything from a small utility closet to a large parking bay.

Tunable White Technology: Each model features on-demand adjustable color temperature (3000K Warm White, 4000K Neutral White, 6500K Cool White).

This allows end-users to customize the ambiance for each specific task or time of day, enhancing functionality and user comfort.

Sizes & Wattage: Ø230mm (18W), Ø270mm (24W), Ø370mm (36W), Ø470mm (42W). This range ensures the right amount of light for everything from a small utility closet to a large parking bay.

Tunable White Technology: Each model features on-demand adjustable color temperature (3000K Warm White, 4000K Neutral White, 6500K Cool White).

This allows end-users to customize the ambiance for each specific task or time of day, enhancing functionality and user comfort.

How to Install

1. Detach the mounting bracket from the main light body.

2. Screw the bracket directly to the ceiling junction box.

3. Simply align and push the main light body onto the bracket until it audibly clicks into place.

This tool-free, one-person process reduces installation time by up to 70% compared to traditional screw-mounted fixtures, directly addressing the primary pain point of electrical contractors: labor cost. This efficiency translates into faster project completion times and higher profit margins on installation contracts.

2. Screw the bracket directly to the ceiling junction box.

3. Simply align and push the main light body onto the bracket until it audibly clicks into place.

This tool-free, one-person process reduces installation time by up to 70% compared to traditional screw-mounted fixtures, directly addressing the primary pain point of electrical contractors: labor cost. This efficiency translates into faster project completion times and higher profit margins on installation contracts.