SKD LED Light Solutions: Simplify Global Trade for Contractors & Distributors

In the global Led Lighting trade, contractors and wholesalers face mounting challenges—sky-high import tariffs on finished lamps, excessive shipping costs, and prolonged lead times—especially when expanding into emerging markets. These barriers not only erode profit margins but also hinder market penetration. Against this backdrop, SKD (Semi-Knocked Down) LED solutions have emerged as a high-efficiency choice, centered on "multi-dimensional cost reduction and trade simplification." Tailored for overseas LED contractors and regional distributors, this solution delivers dual value in cost control and market expansion, effectively addressing core pain points in cross-border LED trade.

Four Core Advantages of SKD LED Solutions:

-- More Competitive Procurement Pricing

SKD kits are priced 5%-10% lower than finished lamps of the same specification, directly reducing distributors' procurement costs and boosting profit margins on bulk orders. The cost advantage stems from eliminating production links such as finished product assembly and specialized packaging, aligning pricing more closely with B2B bulk procurement expectations. For distributors operating on thin margins, this translates to a significant competitive edge in pricing strategies.

-- Dramatically Reduced Shipping Costs

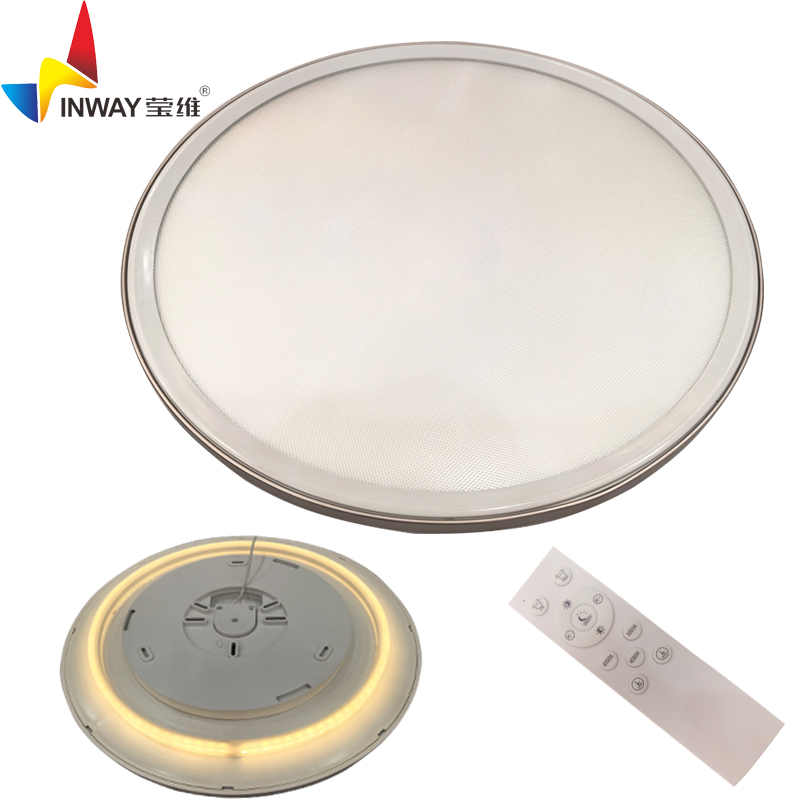

Disassembled SKD components (e.g., Ceiling light bodies, drivers, diffusers)reduce volume by 40%-60%, increasing container loading capacity by over 50%. For example, a 40ft container can hold 3000 finished lamps(size 500mm), while SKD kits can reach 8000 units(with different sizes)—cutting unit shipping costs by 30%-40%. This space optimization directly compresses cross-border logistics expenses, a key cost driver for long-distance LED trade.

--Significantly Shortened Lead Times

SKD production processes are streamlined, by passing full finished product assembly. Regular orders see lead times reduced from 30-45 days (for finished lamps) to 20-25 days. Additionally, components can be produced and shipped in batches: urgent orders prioritize core parts delivery, enabling local assembly to quickly respond to market demand—critical for capturing time-sensitive engineering projects or seasonal sales opportunities.

--Precisely Avoided Tariff Costs

Most countries impose lower tariffs on "unassembled components" than finished lamps, with typical differences of 5%-12%. For instance:

- Brazil: 35%-40% tariff on finished lamps vs. 20%-22% on SKD kits.

- India: 30%-35% on finished lamps vs. 18%-20% on SKD kits.

SKD classification is clearer, reducing risks of tariff supplementary payments due to "finished product classification disputes" and ensuring smoother customs clearance.

The comprehensive benefits of SKD solutions require evaluating "local assembly + venue costs," not just import-side savings:

Assembly Costs: Small-to-medium scale assembly (500 units/day) requires 2-3 workers. In low-labor-cost markets (e.g., India, Vietnam), per-unit assembly costs $1-2—offset by tariff and shipping savings.

Venue Costs: A 50-100㎡ assembly workshop costs $500-1,000/month, with minimal per-unit allocation for bulk orders.

Calculation Logic: Total SKD cost = (SKD procurement price + shipping + tariffs + local assembly + venue fees). Compared to "finished lamp procurement + shipping + tariffs," SKD costs are 15%-25% lower in high-tariff markets.

--Adaptation Cases in High-Tariff Markets

--Adaptation Cases in High-Tariff MarketsBrazil: SKD reduces per-unit comprehensive costs by 22%. A distributor saw 30% higher repurchase rates within 6 months of adoption.

India: SKD shortens lead times from 45 to 22 days, bypassing logistics restrictions. Engineering order acceptance rates increased by 40%.

Algeria: 45% tariff on finished lamps vs. 25% on SKD. Customs clearance rate for SKD exceeds 95% (vs. 80% for finished lamps), minimizing delays.

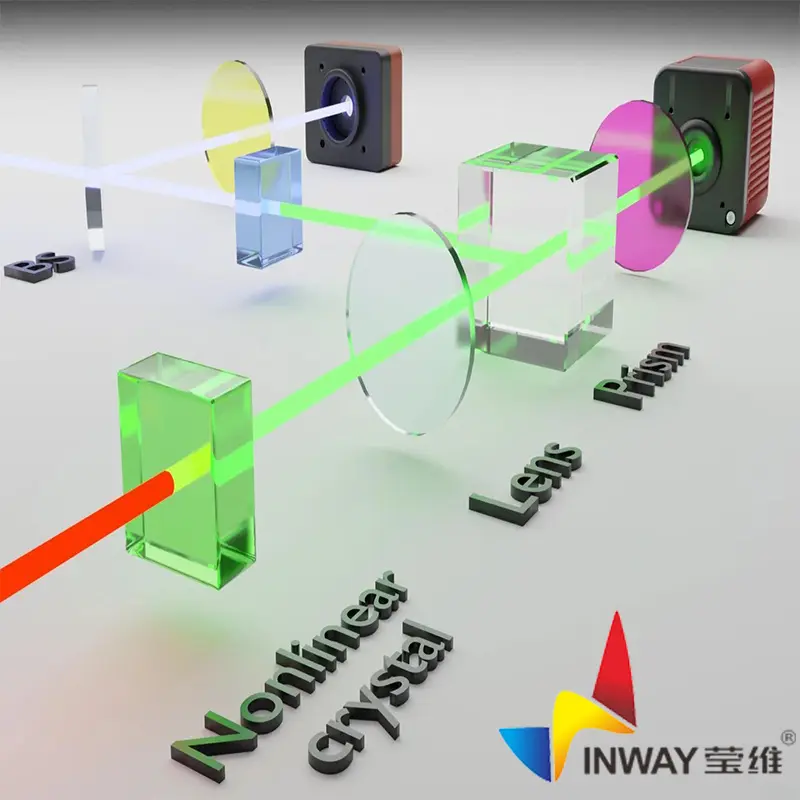

Standardized Kits:Complete "lamp body + driver + optical components + accessory pack" for Ceiling Lights, panel lights, etc., with CE/RoHS certifications.

Localization Empowerment: Free assembly manuals, video tutorials, and one-on-one technical consultants.

Supply Chain Guarantee: 10,000+㎡ factory with core component inventory; bulk orders shipped within 30 days.

SKD LED solutions achieve four-dimensional cost reduction (procurement, shipping, tariffs, lead times), serving as a powerful tool for contractors and wholesalers to break trade barriers in high-tariff markets. Partner with Winway Lighting to customize your exclusive solution and unlock new growth opportunities in the global LED market. Contact us today!